In-Mold Decorating Automation

In-Mold Decorating and In-Mold Labeling Automation

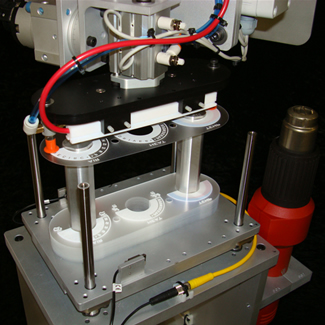

Lenticular Label End of Arm Tool

Custom end of arm tool for automated loading of lenticular labels into pseudo cavities to pre-stage the lenses at the cavity centers for in-mold decorating (IMD) of plastic injection molded cups

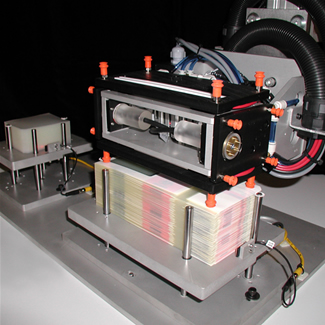

Label Nest With Motion

Custom high tolerance label nest with motion for plastic in-mold labeling (IML) / in-mold decorating (IMD) automation

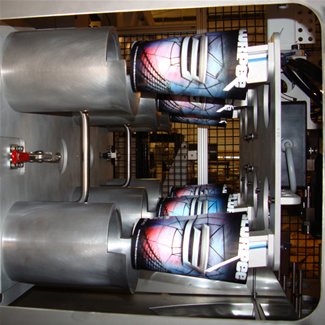

Multi-Label End of Arm Tool

Custom end of arm tool (EOAT) for multi-label application, with built in Pinner bars and servo rotation motion, for plastic in-mold labeling (IML) / in-mold decorating (IMD) automation

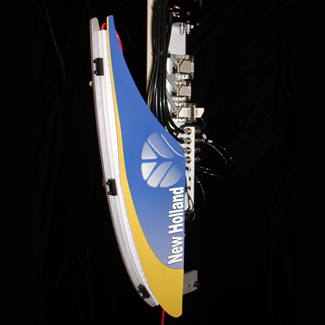

In-Mold Labeling End of Arm Tool

Custom end of arm tool (EOAT) with Simco static charging tetra bars for automated plastic in-mold labeling (IML)

IMD / IML Automation

Robotic Automation Systems specializes in the automation of in-mold decorating (IMD) and in-mold labeling (IML) operations used in plastic injection molding, presses from 15 to 6,000 tons.

- Top Entry/3-Axis Robots – Most conventional

- Side Entry Robots – Faster cycles or if space constraints

Complete turnkey solutions or automation integration for specific applications:

- Outdoor Durable and Packaging

- Flat, Contoured, and Cup/Container

- IML, Foil, and Lenticular

- Single and Multi-Cavity Applications

- Vacuum or Static Label Placement (direct or remote)

- Specialized Cup Automation Cells (single and multi-cavity, two plate or stack mold)

- Label Nest (with/without motion)

- Custom Human Machine Interface (HMI)

Advantages

Use Robotic Automation Systems in-mold decorating (IMD) and in-mold labeling (IML) automation for:

- Faster and Consistent Cycles

- Accurate and Repeatable Label/Decoration Placement

- Increased Operator Safety

- Less Waste

Decorations or labeling via in-mold decorating (IMD) and in-mold labeling (IML) offers numerous advantages and more marketing appeal and options over hot stamping or pad printing, including:

- Up to 5 Color Process in One Shot

- Barcode, Including Sequential Barcodes (for tracking)

- Higher Durability/Scratch Resistant

- Decoration/Labeling Integrated into the Part (better adherence)

- Impervious to UV, Power Washing, Gas, Acid and Other Outdoor Conditions

- Enables Shoot & Ship

- Less Scrap/Waste

Robots

Robotic Automation Systems in-mold decorating (IMD) and in-mold labeling (IML) automation employ 3-axis robots (top entry robots), side entry robots and 6-axis robots (articulated robots) matched specifically to the application, from manufacturers including WEMO Robots, Wittmann Robots, ABB Robotics, FANUC Robotics and Sepro.

End of Arm Tooling

Robotic Automation Systems designs and builds all types of custom end of arm tooling for in-mold decorating (IMD) and in-mold labeling (IML) automation, including confirmation of label pick up, label control to hold label flat to the mold, label placement, and part picking (fixed or movable side), static insulation (remote or direct) and part picking (fixed or movable side), static generation (direct charge) and docking for accuracy and repeatability.

Turnkey Automation Cells

Our custom turnkey IMD / IML cells are complete, including the robot, end of arm tooling (EOAT), table, label nest, guarding and include assembly, installation, and training and support.

Getting Started

Contact Robotic Automation Systems for more examples of our automation solutions for plastic in-mold decorating (IMD) and plastic in-mold labeling (IML), or to start a conversation about how we might help you with your specific application.