Company

About Robotic Automation Systems

The Robotic Automation Systems team provides full-service integration of robotic automation for the plastics industry throughout the United States and North America.

Centrally located within the United States, in Waunakee, Wisconsin, our high quality team of automation experts becomes part of your team to meet and support your automation needs

Expertise and Focus

Our expertise and focus is turnkey robotic automation systems for horizontal and vertical plastic injection molding, including:

- Custom end of arm tooling

- Overmolding automation (press to press transfer automation)

- Insert loading automation

- In-mold decorating (IMD) and in-mold labeling (IML) automation

- Assembly automation

- Vision inspection automation verification

- Packaging & palletizing

- Parts handling

- Parts feeding (feeder bowls and flexible feeding automation systems)

- Sorting, stacking

- Degating

- Routing

- Trimming

- Hot stamping

- Pad printing

- Pre-staging

and all other associated on-line and off-line auxiliary automation operations.

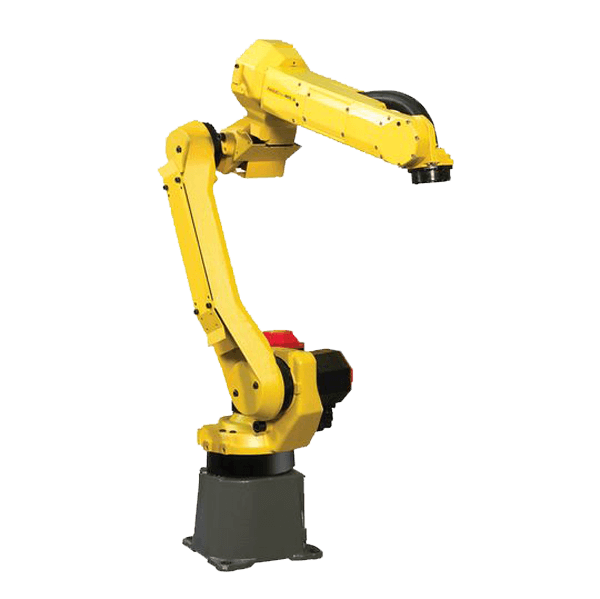

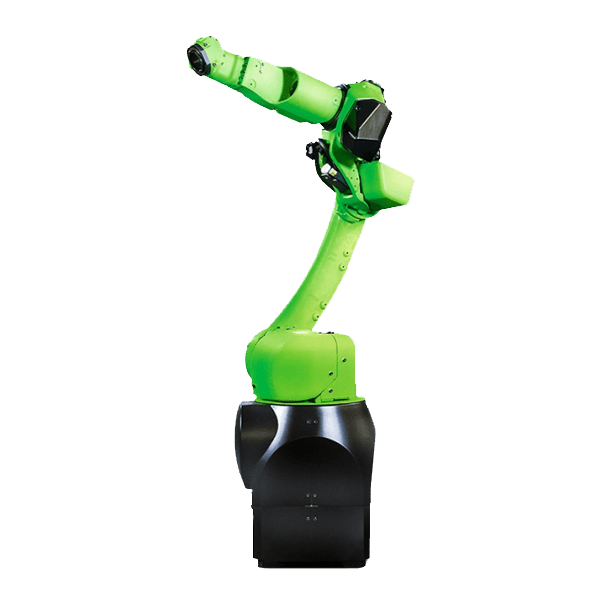

Robotic Automation Systems integrates a wide range of robots from the top robot manufacturers, enabling us to select and integrate the best robots for your specific application – 3-axis robots/top entry robots, 6-axis robots, collaborative robots (cobots), 4-axis SCARA robots, from manufacturers including WEMO Robots, ABB Robotics, Epson Robots and FANUC Robotics.

History

Robotic Automation Systems began as Geiger Handling USA in 1994, as an automation integrator for the plastics industry and North American distributor of Geiger’s quality Swiss robots. We began providing simple solutions to plastic injection molders using 3-Axis pneumatic systems and soon moved into servo robots and other robotic automation.

As our expertise and reputation in the industry has grown, we have become a full service leader of automation for plastics industry, including horizontal and vertical plastic injection molding, insert molding, overmolding, in-mold decorating (IMD) and in-mold labeling (IML), blow molding and all associated on-line and off-line operations.

State-of-the-Art Automation

From entry-level to complex automation solutions, Robotic Automation Systems solutions are helping plastic injection molders increase productivity, reduce scrap, improve part quality, protect their molds, equipment, and personnel, and address workforce shortages.

Starting with fully understanding your operation and needs, through design, engineering, build, full system integration, custom programming / HMI, installation, training and ongoing support – the Robotic Automation Systems Team is here to support you and provide state-of-the-art automation that makes a difference in your business, right down to your bottom line!

Contact Us Today

Learn more about Robotic Automation Systems and hear what our clients have to say about us.

Contact Robotic Automation Systems to start a conversation about your plastic injection molding automation needs and putting our experience to work for you.