Auxiliary Operations Automation Solutions

Auxiliary Operations Automation Solutions

Robotic Automation Systems is a leader and innovator of robotic automation for the plastics industry, providing automation solutions for a full range of plastic molding and auxiliary operations that are custom engineered, built, and fully integrated into your plastic molding application and process – from complete turnkey automation systems to specific robotic automation application needs and tooling.

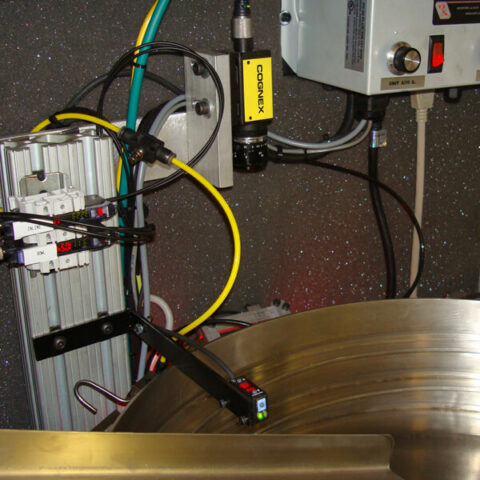

Verification/Inspection

Cognex camera vision inspection system verifying correct insert and orientation as insert leaves the vibrating bowl

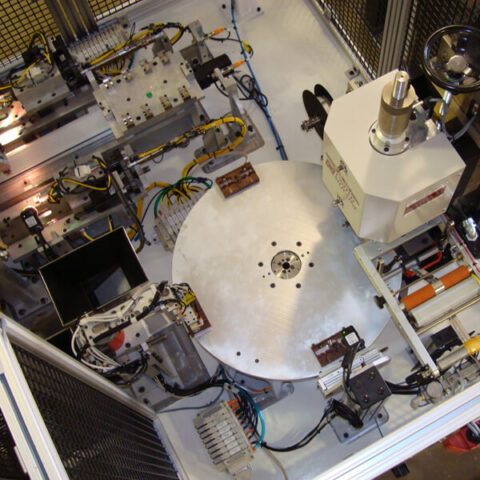

Hot Stamping

Turnkey automation cell with hot stamping, vision inspection, and off-loading operations downstream of the plastic injection molding process

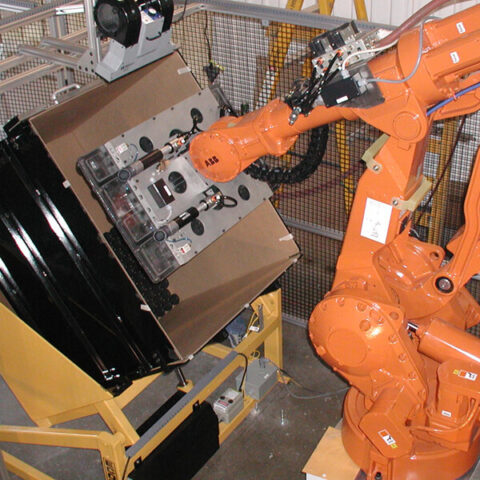

Sorting End of Arm Tool

Mounted on an ABB Robotics IRB 140 robot, sorting by cavity into separate quadrants of a box on a Dorner indexing conveyor

Assembly

Flexible, redeployable assembly cells with vision inspection employing an Epson Scara E2-350 robot

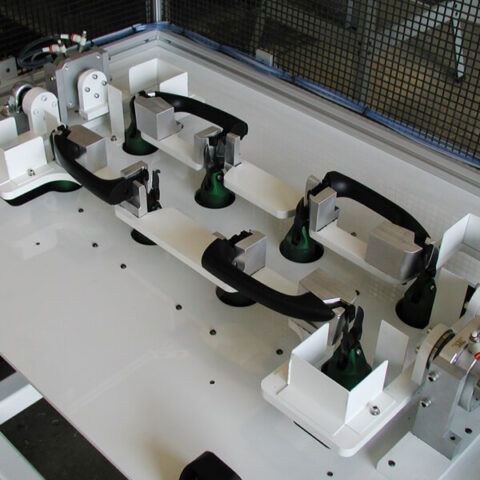

Degating Fixture

For a multi-cavity injection molded automotive door handle with plug insertion device

Pre-Staging

Metal stampings for insert molding are bowl fed and pre-staged at cavity centers for loading and unloading with an ABB Robotics IRB 1600 robot

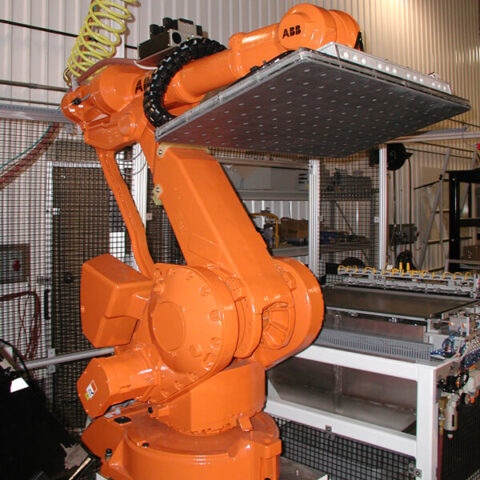

Packaging End of Arm Tool:

High volume vacuum head end of arm tool on ABB Robotics IRB 1600 robot for picking and loading parts into a gaylord

Packaging End of Arm Tool

High volume vacuum head end of arm tool for packaging plastic injection molded parts, mounted on an ABB Robotics IRB robot