In-Mold Decorating (IMD) / In-Mold Labeling (IML) Automation Solutions

IMD/IML Automation Solutions

Robotic Automation Systems is a leader and innovator of in-mold decorating (IMD) automation and in-mold labeling (IML) automation for the plastics industry, providing automation solutions that are custom engineered, built and fully integrated into your plastic injection molding application and process – from complete turnkey automation systems to specific robotic automation application needs and tooling.

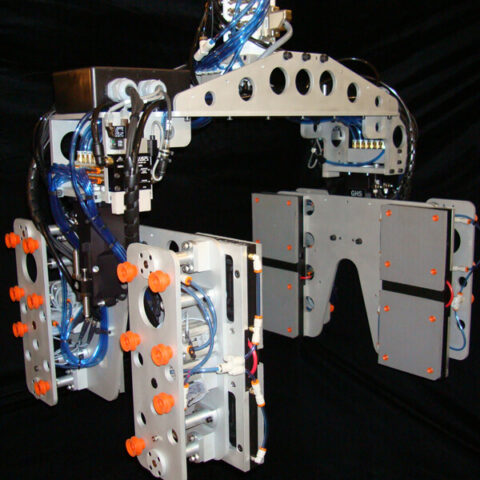

Custom End of Arm Tool (EOAT)

With Simco static charging tetra bars for automated in-mold labeling application

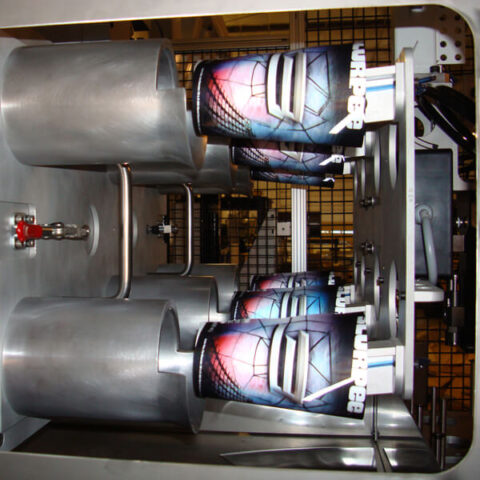

Cup Turnkey Custom Automation Cell

For in-mold labeling (IML) of 12, 16, 22 and 32 ounce straight wall cups and 32 ounce traveler

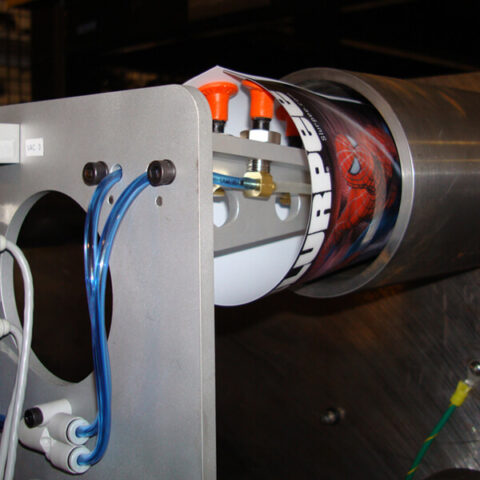

Lenticular Label End of Arm Tool (EOAT)

Custom end of arm tool used in in-mold decorating (IMD) of cups for loading lenticular labels into a mock mold

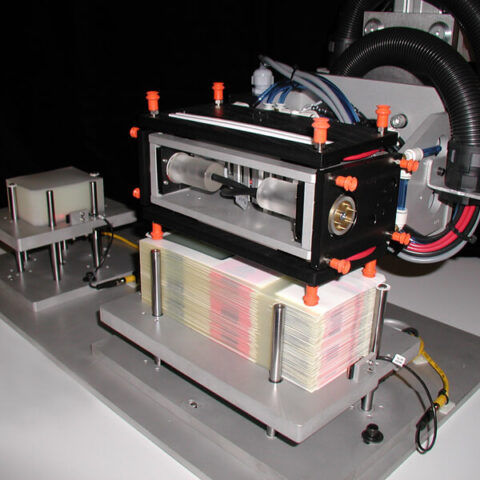

Cup Label Loading End of Arm Tool (EOAT)

Custom end of arm tool for automated loading of labels into a 6 cavity mock mold for in-mold decorating 32 ounce straight wall cups

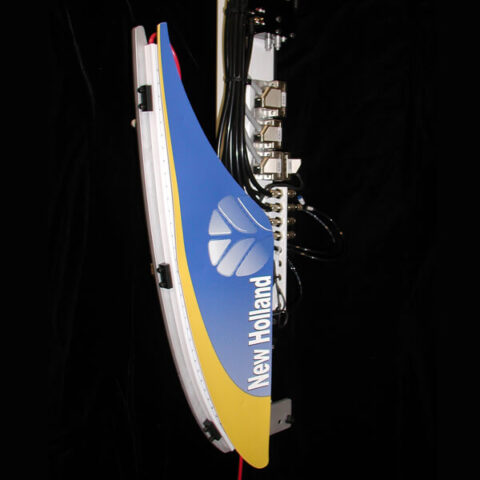

Custom End of Arm Tool (EOAT)

Multi-label applicator (flat labels) for in-mold labeling / decorating, with Pinner bars and servo rotation motion built into the end of arm tool

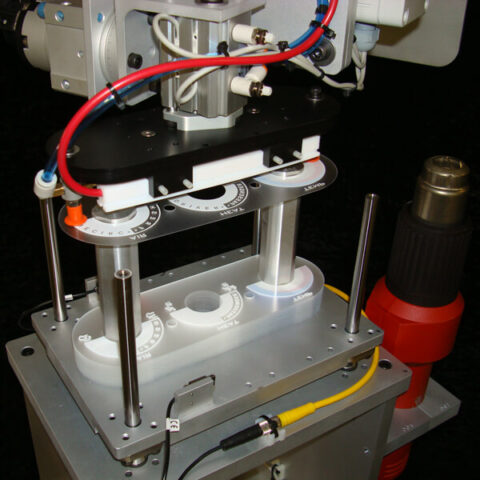

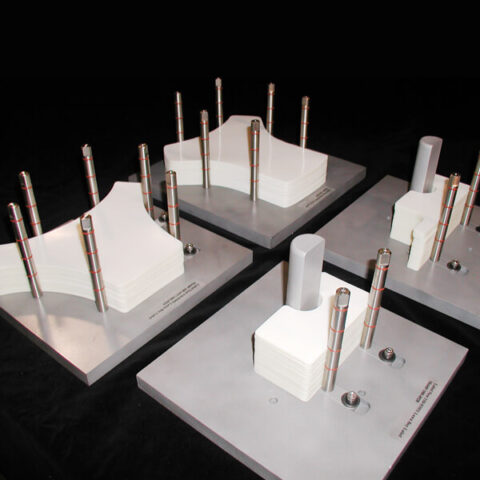

Label Nest (With Motion)

High tolerance in-mold decorating (IMD) custom label nest with motion

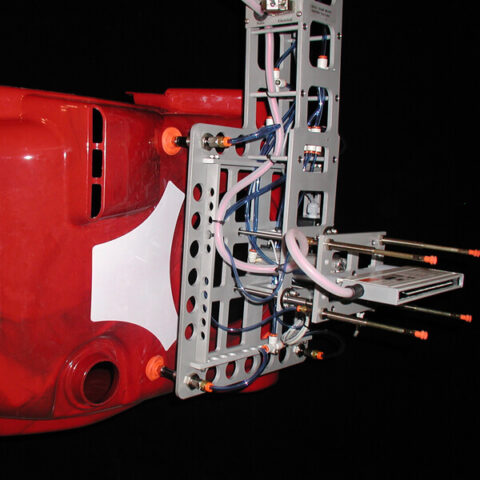

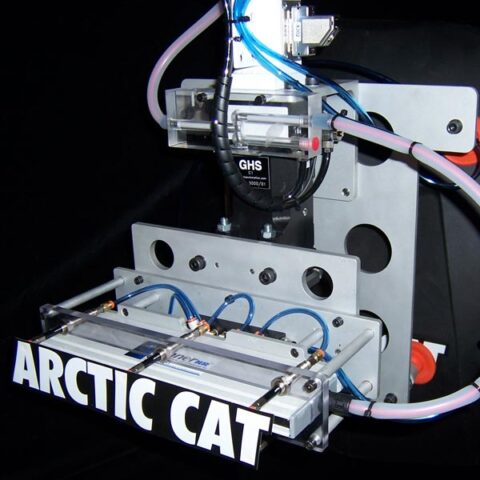

Outdoor Durable Automation Cell (Multi-Label)

Custom turnkey automation cell for in-mold labeling of two labels on a single cavity of an ATV's front fender

Outdoor Durable Automation Cell

Custom turnkey automation cell for in-mold decorating (IMD) a single cavity outdoor durable plastic product

Multi-Cavity End of Arm Tool (EOAT)

Dual function direct charging custom end of arm tool for automated label placement and part picking, mounted on a 3-axis top entry robot

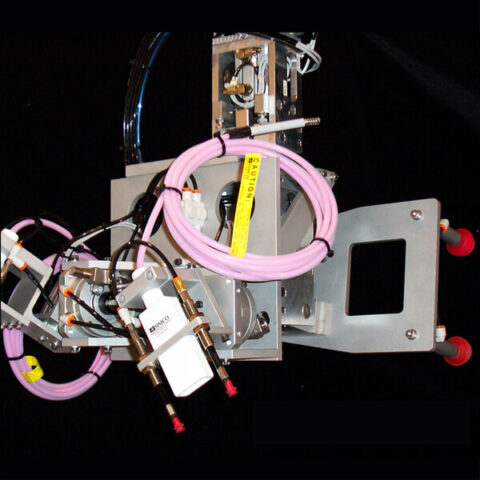

Direct Static Charge End of Arm Tool (EOAT)

Custom end of arm tool with Simco spot chargers for in-mold decorating (IMD) / in-mold labeling (IML) automation

Single Cavity End of Arm Tool (EOAT)

Dual function direct charging custom end of arm tool mounted on a Fanuc Robotics 5-axis robot, for in-mold labeling / decorating and automated part picking of a single cavity plastic molding operation

Label Nest (With Motion)

In mold decorating custom label nest with motion where robot will drive until vacuum confirmation

In mold Decorating End of arm tool with static charging and Part retrieval including vacuum confirmation

Insert Loading Automation Solutions

Robotic Automation Systems is a leader and innovator of insert loading automation for the plastics industry, providing insert loading automation solutions that are custom engineered, built, and fully integrated into your plastic injection molding application and process – from complete turnkey automation systems to specific robotic automation application needs and tooling.